Custom Made Cradle For Our First Grandchild.

The Super Secret Project that I have been working on.

I started by searching the internet for ideas and measurements.

It's amazing how every set of plans for making a cradle for a baby has to be purchased. Anything decent on Amazon cost about 20 bucks. Then the purchase wasn't virtual. The plans had to be shipped. Understandable if the plans were full-sized for making patterns but most weren't.

So actually the Saturday, the 9th of February, 2020 is the day I made the plans and templates for the cradle. It's also the night that my intestines shut down. The following day I ended up in the hospital.

It's amazing how every set of plans for making a cradle for a baby has to be purchased. Anything decent on Amazon cost about 20 bucks. Then the purchase wasn't virtual. The plans had to be shipped. Understandable if the plans were full-sized for making patterns but most weren't.

So actually the Saturday, the 9th of February, 2020 is the day I made the plans and templates for the cradle. It's also the night that my intestines shut down. The following day I ended up in the hospital.

The materials, all cherry wood arrived while I was in the hospital.

The Day after I got out I started rough-cutting the parts for the cradle.

The Day after I got out I started rough-cutting the parts for the cradle.

Headboard and footboard glue-ups. The Jointer is on them to keep them weighs about 30lbs. A good weight to keep the glue-ups flat.

Head and footboards being glued up and clamped.

The Side Rails.

Setting up a support leg.

The base for the support.

Double-checking the Spindle size

I was going to use biscuits but decided that dowels would be stronger.

Over 36 years ago, I built a changing table using the same doweling jig and many other tools that I use today. The changing table was for our son, our first grandchild's Father.

One side dry fitted.

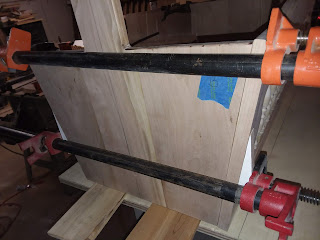

Glue-up and clamped.

Sides built.

I designed the curve designs on the fly during the build. Made patterns to keep every piece matching.

All square edges have been rounded over with the router.

I designed the curve designs on the fly during the build. Made patterns to keep every piece matching.

All square edges have been rounded over with the router.

The build commences.

Again with the dowels for the joints. This joint will be one of the most stressed on the entire Cradle.

Nice and tight.

One never has enough clamps. This required old school methods.

And let's do it again.

Both supports for the cradle built

Installing the Head and Footboards. I biscuited these onto the side rails.

More clamping.

All glued up. I use wedges to provide a flat edge for the clamps.

The base installed.

Cradle Supports are ready for the install. Almost.

Cradle Swing bearings installed.

Cradle swing stop installed.

Final sanding with 200 grit, cleaned with alcohol and now for applying the stain.

Stain color, Walnut.

Wax on, wax off method of staining.

I purchased these large flat head bolts to use when putting the cradles supports spreader together.

Cradle Support Complete

My own little invention.The Rocker Stopper

4 coats of a polyurethane finish.

Rubber feet for the legs.

Cradle Completed.

Took a week's labor and close to $400.00 for the materials. The mattress should be here tomorrow.

No comments:

Post a Comment